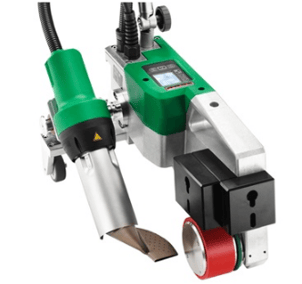

Following are answers to some of the most frequently asked Leister UNIROOF AT questions.

Why does my UNIROOF AT switch on automatically after the blowers have been switched on?

Why does my UNIROOF AT switch on automatically after the blowers have been switched on?If the air temperature is more than 212°F when the device is switched on, the device switches automatically to Cool Down mode. The cooling process is finished when the air temperature is less than 212°F for two minutes.

When in Standby operation, the heat is switched off automatically after a certain period of time. The user sets this time period in Settings.

Check the drive speed, welding temperature and air volume. These need to be adjusted for each job based on environmental conditions and material. Always test your settings on scrap material before working on the final material.

Clean welding nozzle (9) with wire brush. If welded material is blocking the nozzle air holes, not enough heat is reaching the material. In addition, this heat back up can eventually cause your heating element to break.

Double check that your welding nozzle (9) is properly aligned with the welder and the material. See the diagram and dimensions below.

.png?width=488&name=Leister-UNIROOF-AT-Nozzle-Diagram%20(1).png)

A = 42 mm +/-2

B= 1-2 mm

C = 1 mm

Check mains voltage. If there’s not enough power feeding the heating element, it will struggle to reach the proper temperature.

Check that the heating element is working properly. If it’s broken, you’ll notice reduced heat, and in some cases only part of the element will light up when looking at the front opening. NOTE: Avoid getting too close to the opening when checking the heating element while the machine is on.

Reduce air volume. Certain, higher temperatures can’t be reached with the air volume at 100%. By lowering the air volume, the air has more time to heat up, enabling the machine reach higher temperatures.

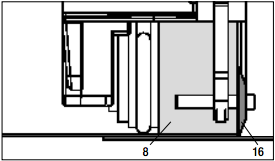

Align the track guide roller (16) so that it is parallel and linear to the drive/pressure roller (8) (see welding sequence).

© 2026 Hy-Tech Products, Inc. All rights reserved. Terms of Use