Recently, a VARIMAT V2 customer came to us because his welder had shorted out and would no longer turn on. We quickly found the cause of the issue. The plug that connects to the machine’s power cord was changed from the 3-pronged 240V Leviton Wetguard plug we installed on the machine before it was sold to a clamp plug.

Clamp plugs attach by tightening two brackets down on opposite sides of a cord. When this happens, plastic fins on both brackets crimp the power cord, restricting the amount of electricity that can flow through (see right). This leads to a power back-up within the machine, which can melt compontents, catch wiring on fire, and short-out circuit boards.

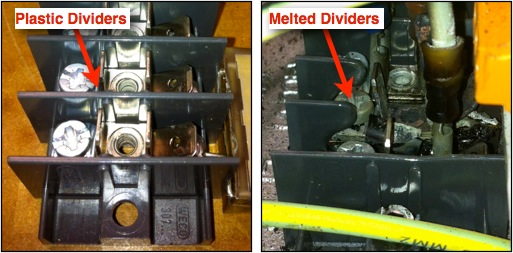

In our customer’s situation, the electricity built up on the welder’s connecting strip, which is where incoming power is dispersed throughout the VARIMAT V2. As you can see from the pictures below, the plastic dividers (left) that keep the connecting posts separated were melted away (right). This lead to sparking between the ports and caught the surrounding wires on fire.

The power buildup then overloaded and melted the ribbon cable (left), and shorted out the VARIMAT V2 e-Drive’s circuit board (right).

In addition, the connecting cable that carries power to the VARIMAT V2’s Electron hot-air blower caught fire and its connector melted (see right).

In addition, the connecting cable that carries power to the VARIMAT V2’s Electron hot-air blower caught fire and its connector melted (see right).

All together, repairs and replacement parts cost this customer more than $1,000.

Proper 240V Plug Selection

To avoid these issues, you should only use plugs that secure to a cord through a compression nut. This nut slides around the cord, and as the plug is screwed together, the nut evenly constricts around the circumference of the cord. This even pressure allows for a secure connection without the threat of restricting electricity flow. See the difference between the two plugs below.

If you have any questions on the type of plug you should be attaching to your roofing equipment, contact us at 800-635-0384 or info@hy-techroof.com.